In the dynamic world of construction and infrastructure development, the role of aggregate equipment is paramount. These machines, from powerful crushers to intricate screeners, form the bedrock of material processing. As technology surges forward and industry demands evolve, the future of aggregate equipment supplier is set to witness groundbreaking innovations and trends. In this blog post, we’ll journey into the heart of these key developments, exploring how they’re poised to reshape the industry.

Automation & AI: The Dawn of Intelligent Machines

The convergence of automation and artificial intelligence (AI) stands as a transformative force in the aggregate equipment landscape. With the relentless progress in machine learning and robotics, these machines are becoming increasingly intelligent, capable of handling complex tasks with minimal human intervention. Envision autonomous crushing plants and robotic screening systems – a glimpse into the future where AI-driven efficiency reigns supreme.

- Unleashing Productivity: Automation liberates aggregate equipment from the constraints of human limitations, enabling continuous operation and a significant boost in productivity. By minimizing errors and optimizing workflows, these smart machines process greater volumes of material in record time.

- Elevating Safety Standards: Automation empowers the industry to create safer work environments by relegating hazardous tasks to machines. This reduces the risk of accidents and injuries, safeguarding the well-being of the workforce.

- Cost-Efficiency Redefined: While the initial investment in automation might seem substantial, the long-term benefits are undeniable. Reduced labor costs, minimized downtime, and optimized resource utilization translate into substantial financial gains for aggregate equipment operators.

Electrification: Pioneering a Sustainable Path

The global shift towards sustainability is driving the electrification of aggregate equipment. By replacing conventional diesel engines with electric motors, the industry takes a giant leap towards reducing its carbon footprint and fostering a greener future.

- Emissions Reduction: Electric motors boast zero tailpipe emissions, offering a cleaner alternative to their diesel counterparts. The transition to electric aggregate equipment significantly curtails greenhouse gas emissions and contributes to improved air quality.

- Lower Operational Costs: Though the upfront cost of electric aggregate equipment might be higher, the long-term savings are substantial. Electric motors require less maintenance and have lower fuel costs, leading to considerable financial benefits over time.

- Performance Reimagined: Electric motors deliver instant torque and smoother operation, enhancing performance and productivity. The absence of gearboxes and clutches results in faster acceleration and unparalleled control, elevating the operational experience.

Connectivity & Data Analytics: Harnessing the Power of Information

The fusion of the Internet of Things (IoT) and advanced data analytics is revolutionizing how aggregate equipment is managed and operated. By connecting machines to the cloud and capturing real-time data, operators unlock valuable insights into equipment performance, maintenance requirements, and production efficiency.

- Predictive Maintenance: Through the analysis of sensor data and other connected devices, operators can anticipate equipment failures and proactively schedule maintenance. This approach minimizes downtime, reduces repair costs, and extends the lifespan of aggregate equipment.

- Production Optimization: Data analytics empowers operators to identify bottlenecks and optimize workflows for enhanced efficiency. By tracking key performance indicators and analyzing production data, informed decisions can be made to maximize output and minimize waste.

- Remote Monitoring & Control: Connectivity grants operators the ability to monitor and control aggregate equipment remotely. This capability enhances operational efficiency, reduces labor costs, and improves safety by enabling real-time intervention when necessary.

The Aggregate Equipment Supplier: Catalysts of Innovation

As the industry progresses, aggregate equipment suppliers play a vital role in driving innovation and delivering cutting-edge solutions. Through investments in research and development, collaborations with technology partners, and a keen understanding of emerging trends, these suppliers shape the future of aggregate equipment.

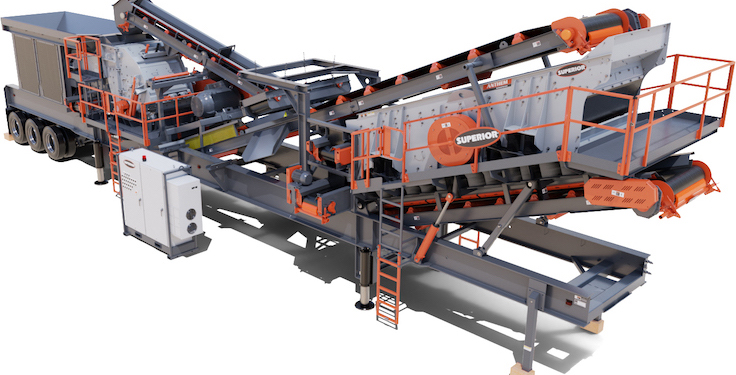

- Pioneering New Technologies: Aggregate equipment suppliers constantly push the boundaries of innovation, developing groundbreaking technologies that elevate performance, efficiency, and sustainability. From advanced crushing systems to intelligent screening solutions, these suppliers lead the charge in technological advancement.

- Empowering Customers: As aggregate equipment becomes increasingly complex, suppliers offer comprehensive customer support and training programs. By educating operators on the latest technologies and best practices, they empower their customers to extract maximum value from their investments.

Conclusion

The future of aggregate equipment is brimming with possibilities, driven by innovations and trends that are set to redefine the industry. From the integration of automation and AI to the adoption of electrification and the power of data analytics, these developments will revolutionize material processing, leading to unprecedented levels of efficiency, productivity, and sustainability. As the industry continues its transformative journey, aggregate equipment suppliers will remain at the forefront, driving innovation and providing cutting-edge solutions that shape the future of construction and infrastructure development. By embracing these trends and investing in the latest technologies, the industry can build a more sustainable and prosperous future for all.